Dynamism. Performance. Intelligence. A Turbo in every detail

They are decisive for performance values and energy efficiency: the impellers, drive motors and frequency converters in each variable frequency controlled unit. That is why we have something against standards in this regard. Instead: key components developed especially for different areas of application. So that when we call it a Turbo, it really is a Turbo.

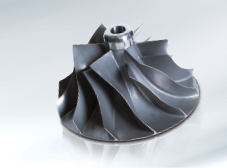

Optimally designed: the impeller design.

What distinguishes an Aerzen Turbo impeller from a regular turbo impeller? Basically everything. Take design, for example. The Aerzen Turbo Generation 5 is the result of complex CFD-based flow analyses. Each impeller is carefully designed to meet the needs of particular classes of performance. That is why Aerzen Turbo impellers are considerably more effective than those where diameter is the only customized element.

Another unique AERZEN feature is the material used: stainless steel instead of aluminum. This allows for decidedly better aerodynamic properties. And stainless steel also means better efficiency, greater longevity, and consistently lower lifecycle costs. This is because stainless steel is practically abrasion-free and corrosion-resistant.

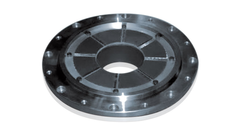

Intelligent security: the frequency converter.

New: the Aerzen Turbo frequency converter (TFC), which controls only the rotational speed based on the motor current. Guide vanes are not moved. There are advantages to this. The TFC is simpler in construction, more reliable, and completely maintenance-free. And much more efficient in operational performance, thanks to the high rise-to-surge (active pump protection), a new technology from AERZEN. This makes the TFC (compared to other standard industrial converters) less sensitive to pressure fluctuations, more responsive, and more stable in operation over the entire range of the turbo map. This is also the basis for an operational combination with displacement and continuous-flow machines.

All parameters are constantly monitored to prevent uncontrolled surge line shutdowns during unexpected fluctuations. This makes the TFC a decisive factor in the operational safety of aeration tanks. Another unique feature: this frequency converter was created by AERZEN’s own R&D innovators. Another pioneering success from Turbo technology.

The Aerzen Turbo impeller

The Aerzen Turbo impeller Simply superior: the PMS motor air foil bearings

Simply superior: the PMS motor air foil bearings Integrated frequency converter, with pullout cabinet

Integrated frequency converter, with pullout cabinetDriven by innovation: the PMS motor.

There is a special motor driving the Aerzen Turbo: the permanent magnet synchronous (PMS) motor. Its characteristics: extremely efficient, energy-saving, highly innovative, and far superior to conventional motors. Because AERZEN developed this motor especially for the Turbo. Because the rotor does not require any additional energy for magnetization. Because, together with the TFC, it was designed to meet the speed and response time requirements of turbo technology. And because this motor demonstrates exceptional performance efficiency of up to 96%, even in partial load operation.

Capable of absorbing any pressure fluctuation:Air foil bearings for the PMS motor

There is a reason the AERZEN PMS motor comes equipped with an air foil bearing system: this technology, borrowed from the aerospace industry, is simple in construction and convincing in function. A cushion of air is created as soon as the shaft begins to rotate. This type of bearing has several advantages over more complex methods:

- Uncomplicated, closed system

- Contact- and vibration-free operation

- Highly functional without the need for peripherals (i.e. electronic control system, retainer bearings, safety bearings, auxiliary electronics such as backup battery systems, etc.)

- No components subject to wear

- Extremely rugged and durable

- 100% maintenance-free

- Able to withstand even large-scale pressure variations

- 100% oil-free

- Energy-saving idle mode